CUSTOMISABLE CONTENT

General Inductions

MINING / CIVIL CONSTRUCTION TRAINING

Real Serious Games was the VR

developer for a number of VR experiences for the mining sector. The target audience for these

experiences were those training to be Apprentices or Maintenance Associates. These experiences were

delivered on mobile headsets.

The following experiences were developed for all students at the Academy:

- VR-01 - Using VR Induction

- VR-02 - Introduction to Manual Handling

- VR-03 - Introduction to Working at Heights

- VR-04- Introduction to Isolation & Tagging

- VR-05- Introduction to Lifting Operations

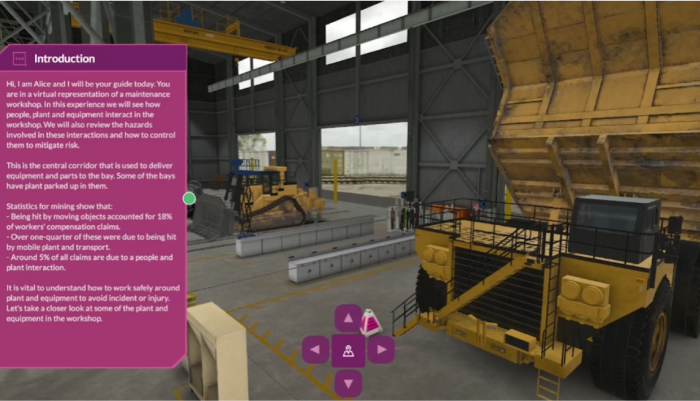

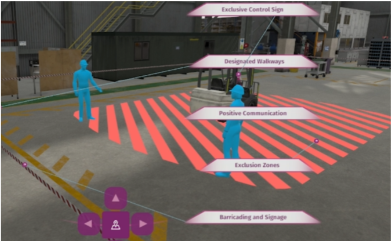

- VR-06 - Introduction to People and Plant Interactions

- VR-07 - Hand Tool Familiarisation

- VR-08 - Power Tool Familiarisation

- VR-10 - BHP Take 5

Available in

Heavy Diesel Fitter Experiences

MINING / CIVIL CONSTRUCTION TRAINING

Real Serious Games was the VR

developer for a number of VR experiences for the mining sector. The target

audience for these experiences were those training to be Apprentices or Maintenance Associates. These

experiences were

delivered on mobile headsets.

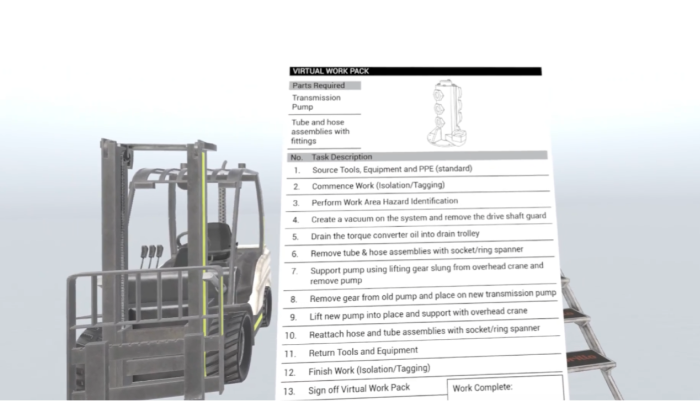

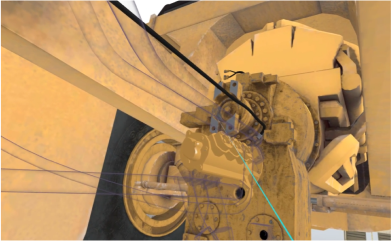

These experiences were developed for the Heavy Diesel Fitter cohort, who were primarily based in the

workshop

environment:

- XM-01 – 793F Equipment Familiarisation

- XM-02 – D11 Equipment Familiarisation

- XM-05 – Introduction to Inspections

- XM-06 – Chasis crack inspections (AR Only)

- XM-07 – Access systems – Inspection

- XM-08 – Task: Remove/replace HT air filters

- XM-09 – Task: Remove/Replace HT Hydraulic Filters

- XM-10 – Introduction to Oil Sampling

- XM-11 – Remove/Replace Transmission Pump

- XM-12 – Accumulators

- XM-13 – Task: Remove/replace steering cylinder

- XM-14 – Task: Remove/replace Torque Convertor

- XM-15 - Task: Remove/replace Turbo

- XM-16 - Task: Remove/replace Starter Motor

Available in

Mechanical Fitter Experiences

MINING / CIVIL CONSTRUCTION TRAINING

Real Serious Games was the VR

developer for a number of VR experiences for the mining sector. The target

audience for these experiences were those training to be Apprentices or Maintenance Associates. These

experiences were

delivered on mobile headsets.

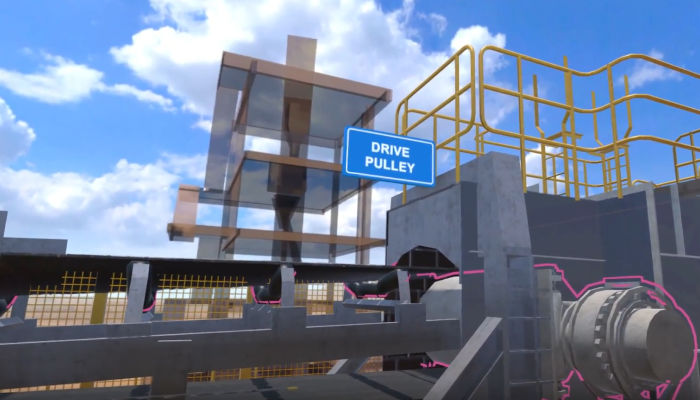

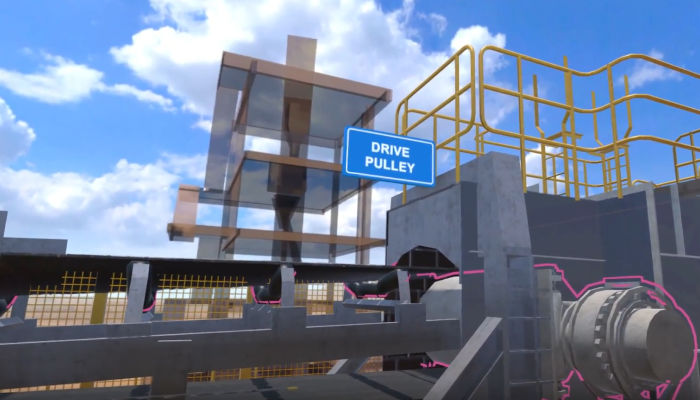

These experiences were developed for the Mechanical Fitter cohort, who were based in the field on the

Coal and Iron Ore

mine:

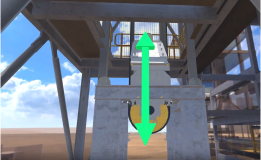

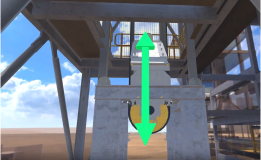

- XF-01 - GTU Tower & Tripper Familiarisation

- XF-02 - Conveyor Inspection

- XF-03 - Remove & Replace Pump

- XF-04 - Crusher Familiarisation

- XF-05 - Flot Cell (Microcel) Familiarisation

- XF-06 - Car Dumper Familiarisation

- XF-07 - Bridge & Portal Reclaimer Familiarisation

- XM-10 – Introduction to Oil Sampling

- XF-08 - Bucket Wheel Stacker/Reclaimer Familiarisation

Available in

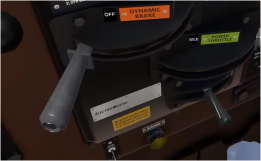

Certificate IV in

Train Driving

Real Serious Games worked with a mining company to develop VR experiences to enhance their

Certificate IV in Train Driving. Seven separate interactive scenarios were developed with the users

driving a train used for hauling iron ore.

These experiences are delivered in conjunction with a motion platform and a VR headset tethered to a PC:

- Application 1: Fatigue Management TLIF2010

- Application 2: Rail Hazard Identification TLIF0020

- Application 3: Yard Operations TLIB2122

- Application 4: Primary Rail Activities and Safety Systems TLIB2122

- Application 5: Rail Safety Equipment TWI2041

- Application 6: Conduct Train Roll-by Inspection LIB3021

- Application 7: Shunt Rolling Stock TLIC3017

Available in

Driving Simulator

Priority Rules

Real Serious Games was engaged by a mining client to develop a VR Priority Rules Experience that will

increase safety

and operational efficiency of the current mining operations. ‘Priority Rules’ are the mine specific

traffic rules that

apply to vehicles (heavy and light) operating on a mine site.

The experience enhances current Priority Rules training by assessing potential truck drivers and

reassessing existing

drivers’ understanding of Priority Rules.

Upon completion of the experience, a report is generated showing the actions and results of the user’s

experience.

This experience is delivered as a seated experience, with a steering wheel and pedals and a tether VR

headset.

Available in

Workplace Health & Safety Training

A series of immersive VR experiences have been developed for some common high risk scenarios. These are delivered on mobile headsets and could be mapped to course requirements.

- Experience 1: Working at Heights: planning the work

- Experience 2: Working at Heights: fall protection equipment

- Experience 3: First Responder

Available in

JOYSTICK OPERATED PLANT

Virtual reality (VR) technology can be used to simulate and enhance the operation of joystick-operated

heavy machinery like plant equipment used in construction, mining, and other industries, particularly for rotation and

bucket operations.

A VR simulation environment is created to replicate the operation of the real heavy machinery. This

environment can include a 3D model of the equipment, the surrounding terrain, and any objects or materials to be

manipulated.

The operator wears a VR headset, which provides a fully immersive experience. Inside the VR headset, the

operator sees a 3D representation of the virtual equipment and its surroundings.

Specialized controllers or joysticks are used within the VR environment to replicate the physical

controls of the real

machinery. These controllers are typically equipped with sensors that track their position and movement.

Using VR for joystick-operated plant machinery training provides a safe and controlled environment for

operators to practice and refine their skills. It also enables operators to experience challenging or dangerous

scenarios without exposing them to actual risks. This technology is particularly useful for training new operators,

ensuring they are proficient and safe when operating heavy machinery.

Available in